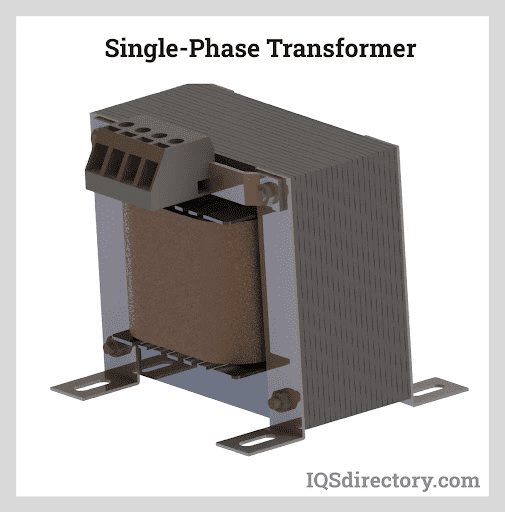

Electric transformers are crucial devices in electrical engineering that facilitate the efficient transmission and distribution of electrical power. They operate on the principle of electromagnetic induction to transfer electrical energy between two or more circuits at different voltage levels. Transformers generally consist of a primary winding and a secondary winding wound around a shared core, which can be made of iron or other magnetic materials. Read More…

With more than 500 current transformer manufacturers in the world, Triad Magnetics realizes you have a choice. Why choose Triad? Having served the needs of many industries for more than half a century, Triad believes its experience makes the difference. And if there is one point experience has taught it, it is that it must remain flexible and adaptable to the changing needs of the market.

Lenco Electronics, Inc. specializes in a wide variety of custom electric transformers. Lenco’s success has not come about by accident, but by providing its customers with high-quality products.

Bicron Electronics specializes in high efficiency toroidal transformers up to 10KVA with safety recognitions from UL, CSA, VDE, TUV and IEC as well as high frequency transformers up to 10MHz for isolation, gate drive, pulse and switch mode functions. Bicron is ISO 9001:2000 certified.

We design and manufacture Toroidal Transformers, Inductors and Current Transformers in Connecticut, USA and Asia. Certified to UL/CSA/IEC/EN. CE marking. Applications from lighting to medical devices. Customers served Worldwide. For High Frequency Magnetics, visit our affiliate www.Induktorusa.com

ISO 9001:2000 registered Sun Transformer creates custom transformers optimized for the needs of many industries. Large power, isolation & auto transformers, printed circuit mount power transformers, units for hostile conditions, units with ferrite or nickel cores for digital telecommunications use, etc.

More Electric Transformer Manufacturers

As alternating current courses through the primary winding of a transformer, it generates a dynamic magnetic field around the core. This ever-shifting field, in turn, induces a voltage across the secondary winding. Depending on how the transformer is set up, this process can either elevate or reduce the power output.

Components of Electric Transformers

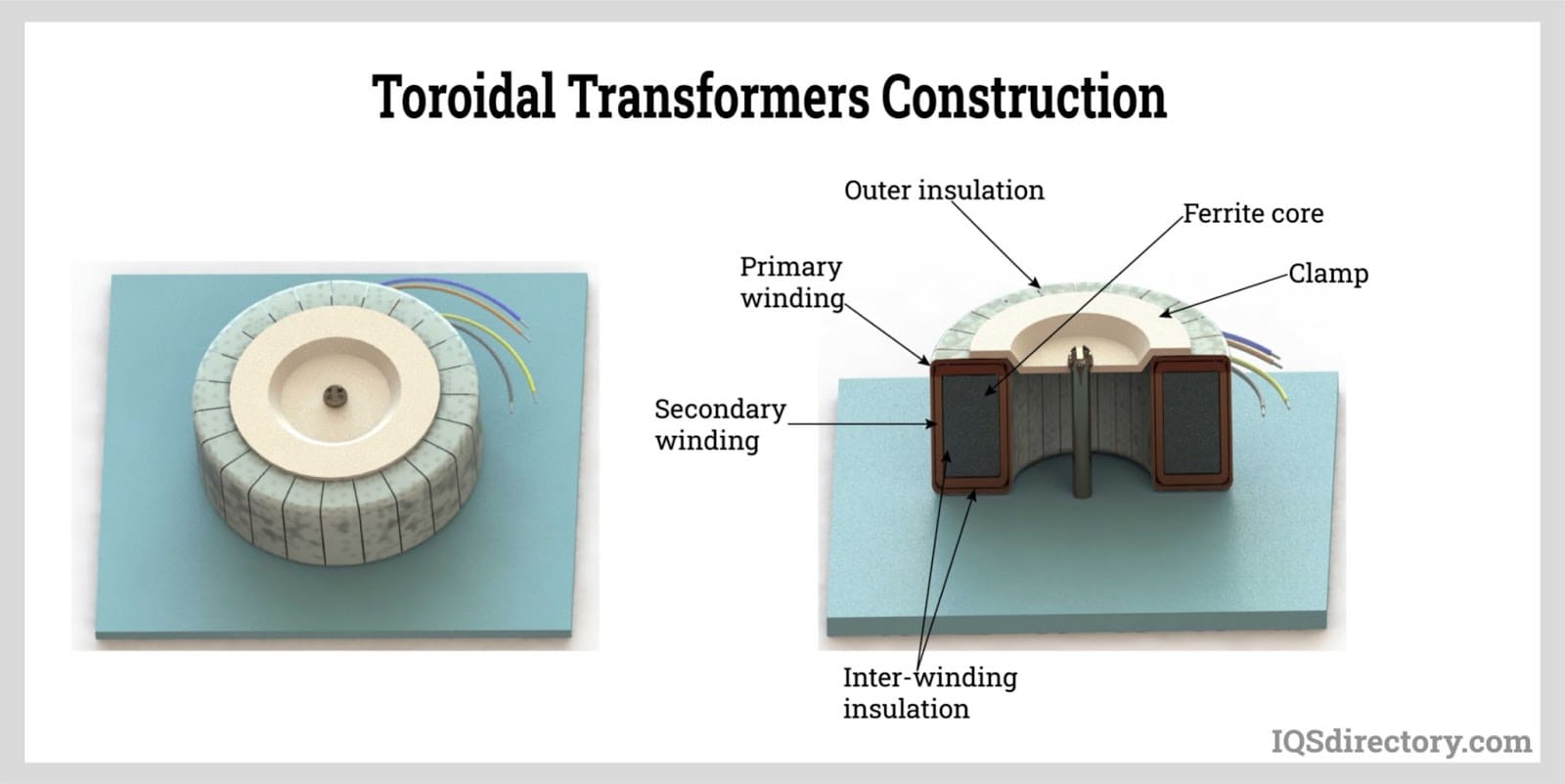

Electric transformers are intricate devices designed to adeptly adjust electrical energy from one voltage level to another. At their heart lies the core, crafted from stacked laminated steel sheets. This core acts as the conduit for magnetic flow, crucially enhancing the magnetic interaction between the primary and secondary windings. This interaction is key for effective electromagnetic induction, helping to keep energy losses at bay. Wrapped around the core are the windings, made from either copper or aluminum, insulated to prevent any conductivity mishaps. The primary winding is where the alternating current resides, sparking a dynamic magnetic field that, through mutual induction, breathes voltage into the secondary winding. The transformation capabilities of the transformer, whether stepping up or stepping down the voltage, hinge on the winding’s number of turns—more turns for stepping up, fewer for stepping down.

Insulation stands as the guardian of transformer design, essential for both safety and reliability. Employing materials like varnishes, tapes, and insulating papers, it acts as a barrier against short circuits and breakdowns under the intense pressures of high voltages. By braving electrical stresses and warding off environmental threats such as temperature fluctuations and moisture, proper insulation not only prolongs the life of the transformer but also guarantees its safe functionality.

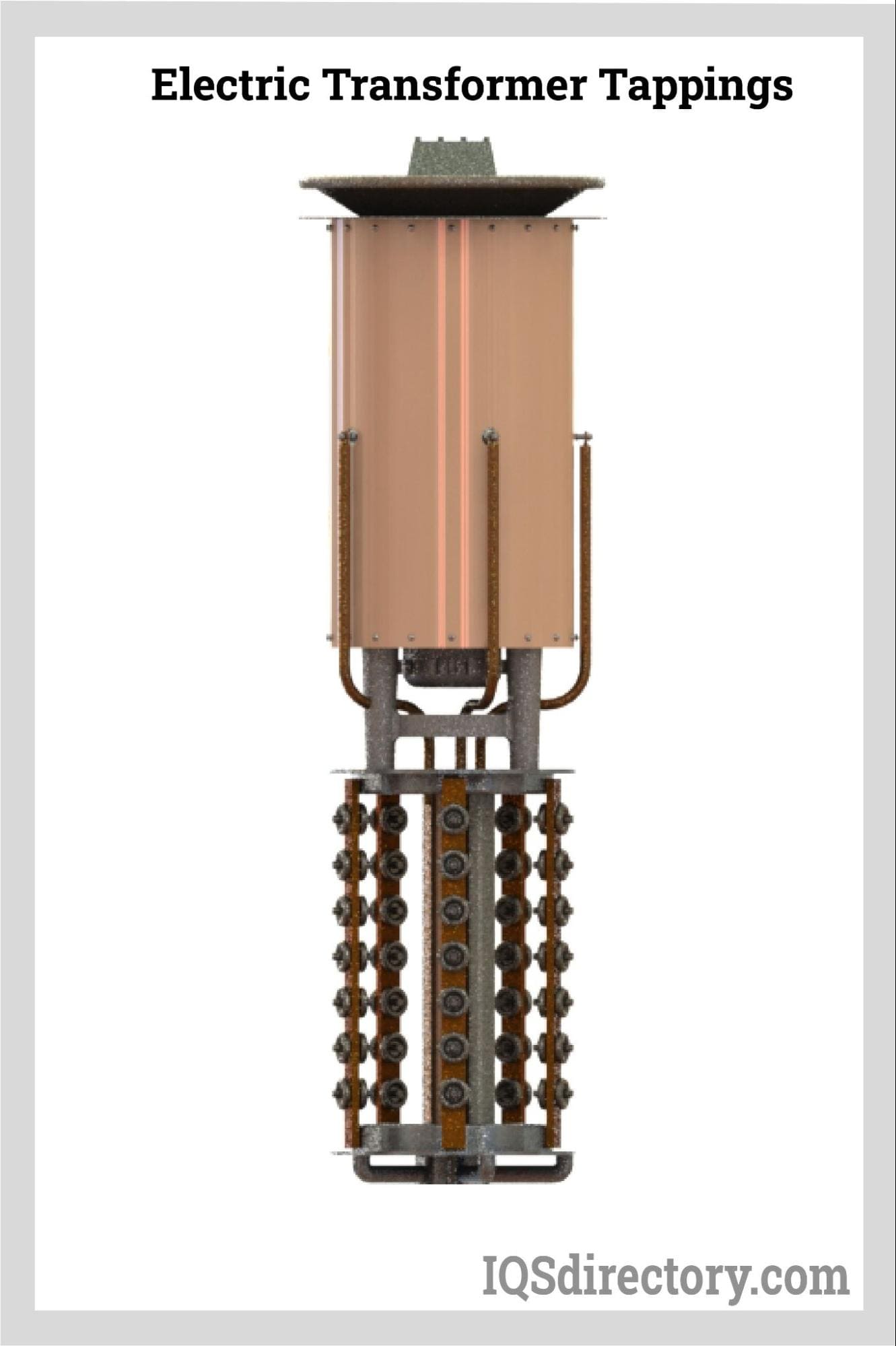

Some transformers come with a tap changer, a versatile component that lets you tweak the windings’ turn count. This functionality is crucial for handling shifts in input voltage or alterations in load demands. By manipulating the tap changer, the transformer’s output voltage is precisely adjusted to align with the required levels, maintaining a consistent flow of electricity through fluctuating conditions.

Transformers inherently produce heat as a byproduct of their operation, stemming from the resistive losses in their windings and core. To combat this, a cooling system is essential to dissipate the heat and keep the transformer’s temperature safely regulated. Two primary cooling methods are utilized: liquid and air cooling. Liquid cooling systems immerse the core and windings in insulating oil, which efficiently absorbs and removes heat. Alternatively, air cooling uses fins or radiators to transfer the heat into the surrounding air. Keeping the temperature within optimal ranges is vital for ensuring the transformer operates efficiently and lasts longer.

The core, windings, insulation, tap changer, and cooling system collaborate to facilitate smooth and efficient power transfer. The core boosts magnetic coupling, the windings enable mutual induction, and the insulation promotes safety. Meanwhile, the tap changer adjusts voltage levels, and the cooling system manages heat dissipation. Together, these components ensure transformers operate effectively across diverse electrical systems and applications.

Functioning of Electric Transformers

Transformers operate on the principle of electromagnetic induction. As alternating current (AC) courses through the primary coil, it generates a magnetic field that traverses the core, prompting a current in the secondary coil. The voltage in the secondary coil depends on the turn ratio between the secondary and primary coils. Transformers are categorized by the voltage levels they handle, ranging from step-up and step-down transformers, which adjust voltage levels up or down respectively, to distribution transformers that manage voltage distribution, instrument transformers that measure electrical parameters, and isolation transformers that safely separate circuits.

Variations of Electric Transformers

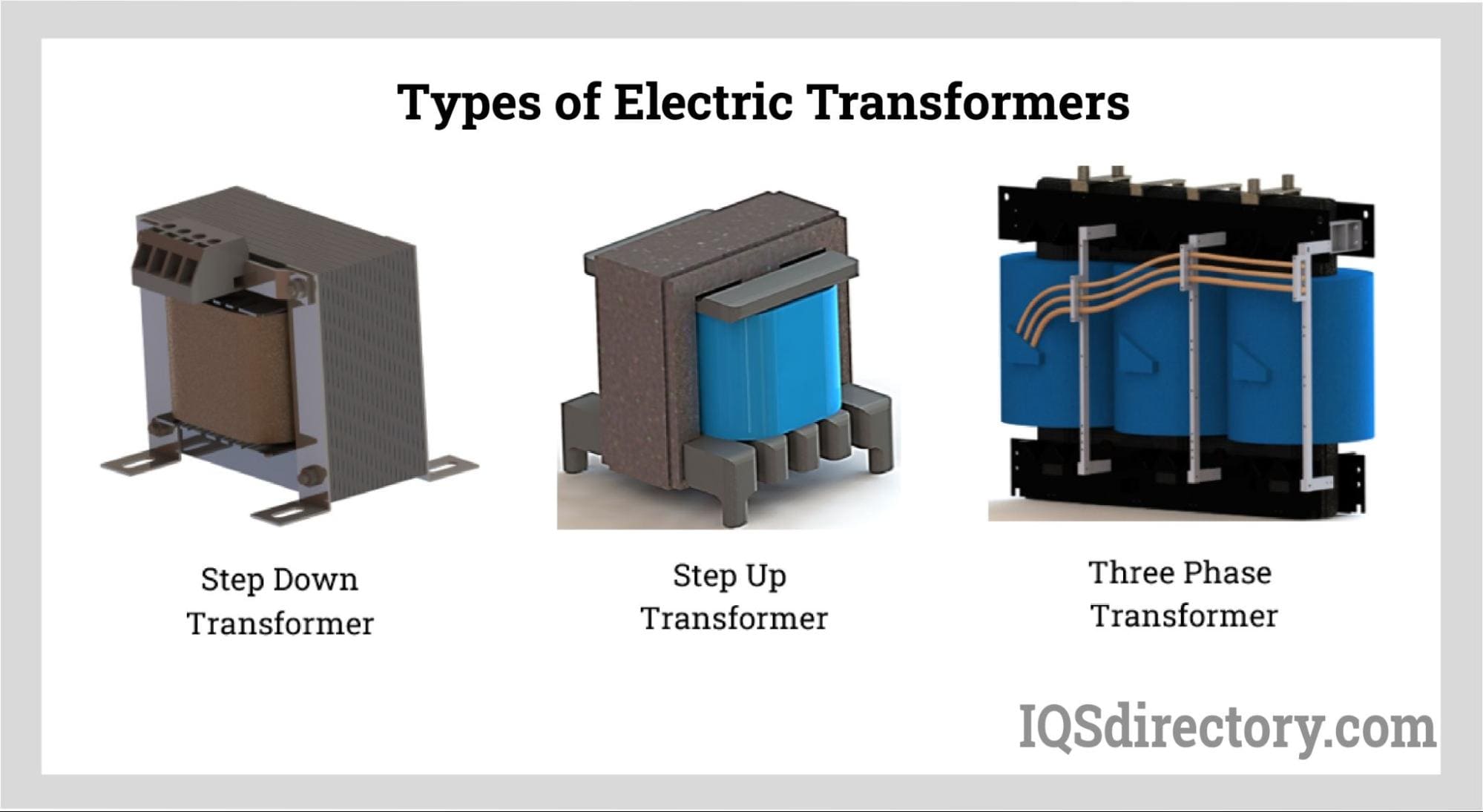

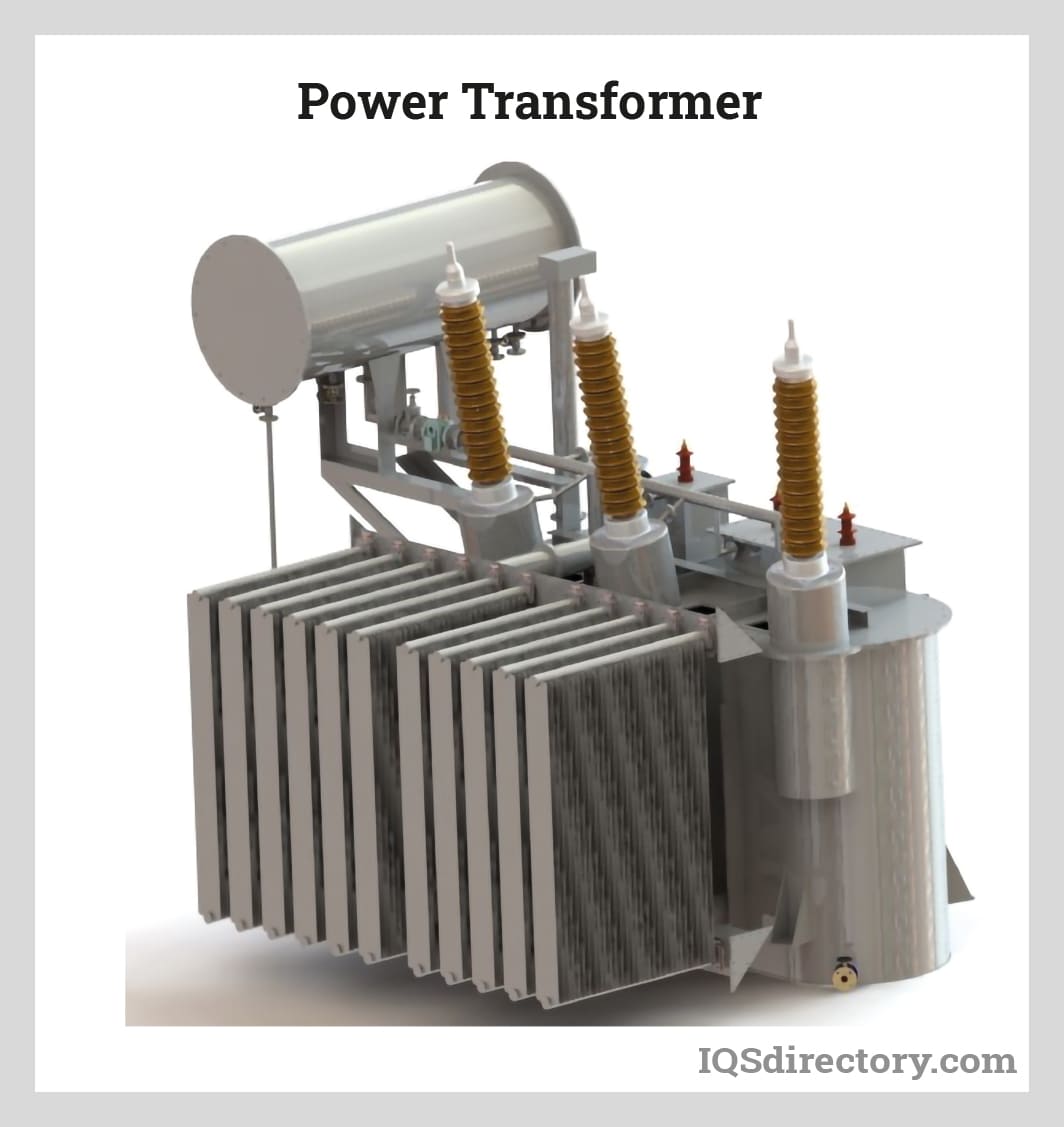

Electric transformers are crafted in diverse designs to suit particular roles across power transmission, distribution, and measurement networks. For example, step-up transformers elevate the voltage from the primary to the secondary winding, a crucial process in power generation facilities. Here, they boost the produced electrical voltage to higher levels suitable for long-distance travel via high-voltage transmission lines. This increase in voltage is vital as it curtails power losses during transmission, thereby enhancing both the economic efficiency and practicality of transporting electricity across vast distances.

Step-down transformers perform the inverse function of their step-up counterparts. They scale down the voltage from the primary winding to the secondary winding. Commonly used in power distribution networks, these transformers tame the high-voltage currents from transmission lines to more manageable, safer levels for commercial, industrial, and residential use. This adjustment guarantees that the electricity reaching consumers is both appropriate and safe for use.

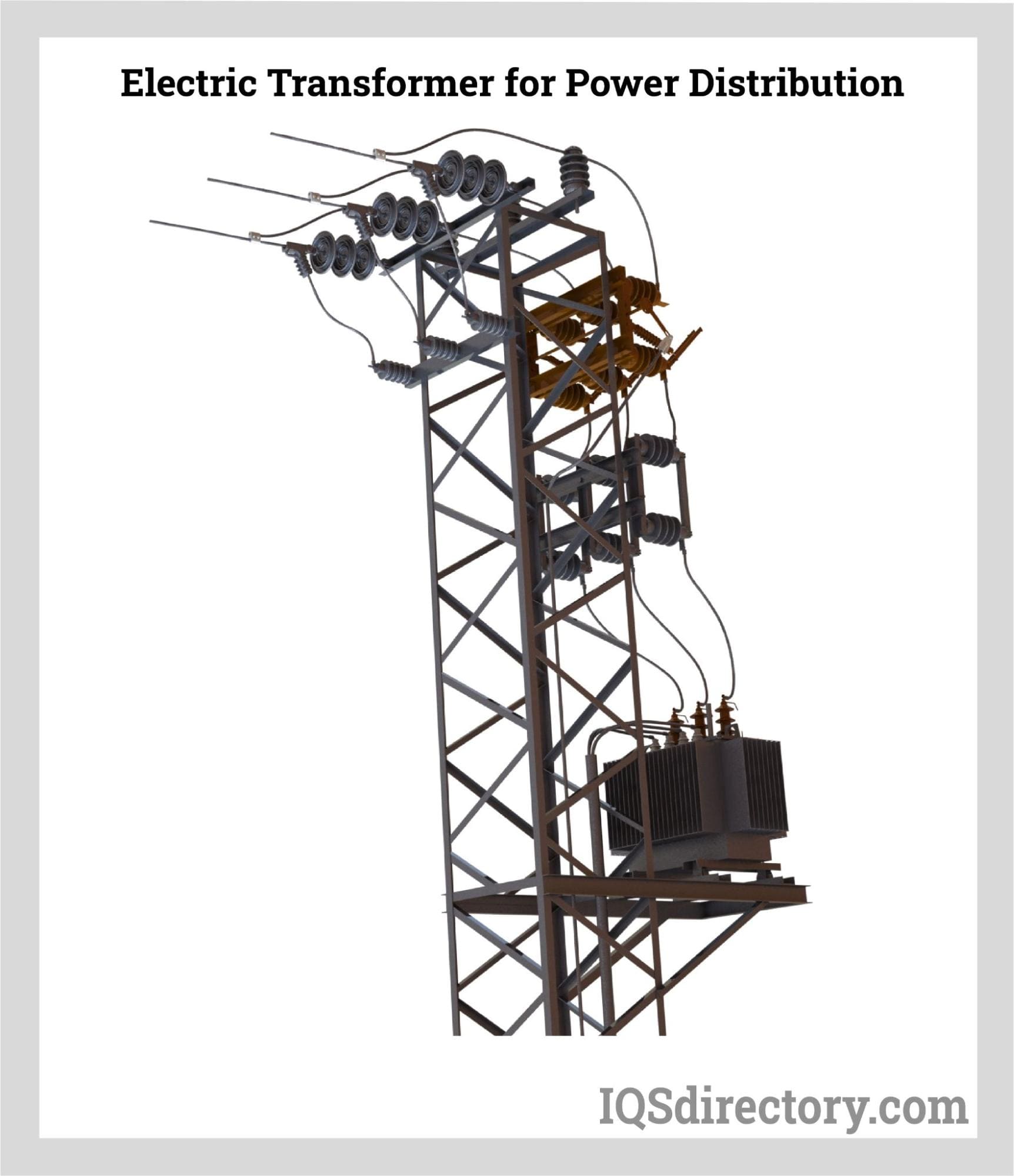

Distribution transformers serve as the final stage in the power distribution process, stepping down the voltage from substations to levels that homes, small businesses, and local industries can use. These transformers are typically perched on utility poles or stationed on concrete pads within residential areas, ensuring a reliable power supply for local communities.

Isolation transformers serve as guardians between different electrical circuits, creating a barrier that ensures electrical separation between the primary and secondary windings. They primarily safeguard against electric shocks and shield delicate electronic devices from harm. Commonly deployed in environments like medical facilities, laboratories, and communication networks, isolation transformers are critical where the dangers of electric shock or electronic interference loom large.

Instrument transformers are specialized devices designed to adapt the power system’s measurements for safety and accuracy in instrumentation and protective mechanisms. They come in two primary forms: potential transformers (PTs, also known as voltage transformers) and current transformers (CTs). Potential transformers tame high voltages to safer, more manageable levels, suitable for tools such as voltmeters and protective relays. Conversely, current transformers scale down intense currents to lesser magnitudes that devices like ammeters and protective relays can handle easily. These transformers play a critical role in ensuring precision and safety in power system management.

Three-phase electric transformers play a crucial role in three-phase power systems, which are prevalent in industrial and commercial settings. Featuring three sets of windings, these transformers excel in transferring power more efficiently and evenly than their single-phase counterparts. They are integral to distributing power, operating industrial machinery, and maintaining continuous and stable energy flows in large-scale electrical networks.

Auto transformers stand out as a unique variation of transformers, featuring a shared winding for both the primary and secondary circuits. By incorporating taps along this winding, they can deliver adjustable voltage outputs. These transformers are particularly useful in scenarios where slight voltage modifications are necessary, such as in voltage regulators and specific motor starters.

Current transformers, previously discussed, are specialized instrument transformers designed to scale down high currents from power systems to more manageable, quantifiable levels. These transformers are crucial in protective devices, energy metering, and monitoring systems. Through precise current measurement, they ensure effective protection and management of electrical equipment and circuits.

The variety of electric transformers are designed to meet specific demands in power generation, distribution, and various industrial uses. Each type plays a distinct role, ensuring that electrical systems operate smoothly and safely across a range of industries and environments.

Limitations and Overcoming Them

Electric transformers are vital for distributing and transmitting power, yet they come with challenges that manufacturers constantly work to improve. These challenges include energy losses, constraints on size and weight, reduced efficiency under low loads, and difficulties in handling high-voltage transmission.

Transformers don’t convert energy with perfect efficiency; some of the electrical energy they handle dissipates as heat. This results from resistive losses in their windings and magnetic losses in their cores. Moreover, transformers can be cumbersome and weighty, particularly the varieties engineered for high voltage and power capacities. Such bulk and heft present practical difficulties in terms of installation, transportation, and fitting into limited urban spaces. Transformers typically lose efficiency under light loads, which results in electrical energy being squandered. Moreover, while high-voltage transmission lines are crucial for transferring power over long distances, they are not without their complications. For instance, the occurrence of corona discharge presents not only power losses but also raises environmental issues.

Manufacturers are tackling these challenges by harnessing cutting-edge technologies and fresh approaches in transformer design and production. For instance, breakthroughs in materials science have ushered in the use of amorphous metals for transformer cores, slashing core losses and boosting efficiency. Moreover, the development of intelligent transformer technologies equipped with integrated monitoring and control systems promises to fine-tune performance and curtail energy waste.

Transformers equipped with digital smarts are on the rise, enabling them to perform real-time monitoring, load forecasting, and predictive maintenance. This proactive approach helps avert potential breakdowns and maintains transformers at peak performance. Additionally, ongoing research in superconducting materials could transform the very blueprint of transformers, minimizing energy wastage nearly to the vanishing point and paving the way for more compact, high-efficiency models.

Manufacturers are venturing into innovative cooling techniques like liquid-immersed transformers using natural ester fluids, enhancing cooling efficiency while reducing environmental footprints. Moreover, initiatives are underway to recycle and refurbish aging transformers, aiming to prolong their service life and curtail waste.

Electric transformers, despite their inherent limitations, are the focus of ongoing improvements as manufacturers invest in technological advancements, state-of-the-art materials, intelligent control systems, and eco-friendly approaches. These persistent endeavors are designed to boost transformer efficiency, minimize energy wastage, and enhance reliability, ultimately fostering a more sustainable and effective electrical power network.

Agencies Overseeing Electric Transformers

In the United States, a tapestry of agencies and organizations orchestrates the development and implementation of electric transformers, prioritizing safety, standard adherence, and seamless integration into the national power grid. Key among these entities is the National Fire Protection Association, which, through its National Electrical Code, sets forth comprehensive guidelines for electrical setups, transformers included, to bolster electrical safety and functionality. Additionally, the Federal Energy Regulatory Commission plays a crucial role in supervising the cross-state electricity transmission, maintaining equitable market practices and the reliability of the grid, with a specific focus on transformer regulation. The North American Electric Reliability Corporation (NERC) rigorously upholds required standards to ensure the reliability and security of the bulk power system, which includes the operation and protection of transformers. Similarly, the Institute of Electrical and Electronics Engineers (IEEE) crafts guidelines for transformer design and testing to foster consistency and safety. Moreover, the National Institute of Standards and Technology (NIST) oversees the precision of electrical measurements, a cornerstone in transformer design and certification. On another front, the Department of Energy (DOE) champions the research and implementation of energy-efficient transformers, thereby driving progress and enhancing grid efficiency. Collectively, these organizations collaborate to set benchmarks, fuel innovation, and guarantee the safe and effective utilization of electric transformers within the nation’s electrical framework.

Applications of Electric Transformers

Electric transformers are integral to numerous industries, including power generation, transmission, and distribution, as well as manufacturing, transportation, telecommunications, mining, oil and gas, military, and medical fields. They play a crucial role in ensuring efficient power transmission and supplying various equipment and devices. Let’s delve deeper into these specific applications.

Power Generation Industry: Electric transformers in power generation plants boost the voltage of electricity to high levels, enabling efficient transmission over long distances.

Power Transmission Industry: Electric transformers play a crucial role in power transmission by reducing high-voltage electricity to a lower, safer voltage for distribution to homes and businesses over shorter distances.

Power Distribution Industry: Electric transformers play a crucial role in power distribution, reducing high-voltage electricity to safer levels suitable for use in homes and businesses.

Manufacturing Industry: Electric transformers are essential in manufacturing processes, delivering power to a wide array of machines and equipment.

Transportation Industry: Electric transformers power the motors that drive trains and trams, ensuring their smooth and efficient movement.

Telecommunications Industry: Electric transformers provide power to essential telecommunications equipment, including routers, switches, and servers.

Mining Industry: Electric transformers provide essential power to the heavy machinery involved in mining operations, supporting tasks such as excavation, drilling, and hauling.

Oil and Gas Industry: Electric transformers play a crucial role in oil and gas exploration and production by supplying power to pumps, compressors, and various other equipment.

Military Industry: Electric transformers play a vital role in military equipment, powering radar systems, communication networks, and various electronic devices.

Medical Industry: Electric transformers power medical devices like MRI machines, X-ray machines, and CT scanners, ensuring they operate accurately and reliably.

The Future of Electric Transformers

The future of electric transformers is poised to be shaped by technological innovation and a focus on sustainability. Smart and digital transformers, equipped with real-time monitoring and control features, could improve grid stability and optimize energy distribution. High-efficiency transformers, utilizing advanced materials and cooling techniques, are expected to reduce energy losses in power transmission and distribution. Superconducting transformers, with their near-zero resistance, promise to minimize energy wastage and allow for more compact designs. As renewable energy sources and energy storage solutions become more common, transformers will need to handle bidirectional power flow and support decentralized grids. Manufacturers are expected to prioritize eco-friendly designs, using sustainable insulation materials and recycling initiatives to lessen environmental impact. The future of electric transformers is set to feature greater intelligence, efficiency, and adaptability, leading to a more resilient, sustainable, and interconnected electrical infrastructure.

Choosing the Right Electric Transformer Supplier

To achieve the best results when purchasing electric transformers, it’s essential to compare multiple suppliers using our comprehensive directory. Each supplier has a dedicated business profile showcasing their expertise and capabilities, complete with a contact form for direct inquiries or quote requests. Utilize our patented website previewer to swiftly understand each company’s specialties. Finally, our streamlined RFQ form allows you to easily reach out to several suppliers with a single submission.

Electric Coils

Electric Coils Electric Switches

Electric Switches Electric Transformers

Electric Transformers Electronic Connectors

Electronic Connectors Electronic Enclosures

Electronic Enclosures EMI Shielding

EMI Shielding Membrane Switches

Membrane Switches Power Cords

Power Cords Static Eliminators

Static Eliminators Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services