The Zig Zag transformer, also known as "interconnected star winding," is a special-purpose transformer used in power systems. It acts as a barrier between the ground and the component, preventing the system component from being damaged by fault currents. Read More…

With more than 500 current transformer manufacturers in the world, Triad Magnetics realizes you have a choice. Why choose Triad? Having served the needs of many industries for more than half a century, Triad believes its experience makes the difference. And if there is one point experience has taught it, it is that it must remain flexible and adaptable to the changing needs of the market.

Lenco Electronics, Inc. specializes in a wide variety of custom electric transformers. Lenco’s success has not come about by accident, but by providing its customers with high-quality products.

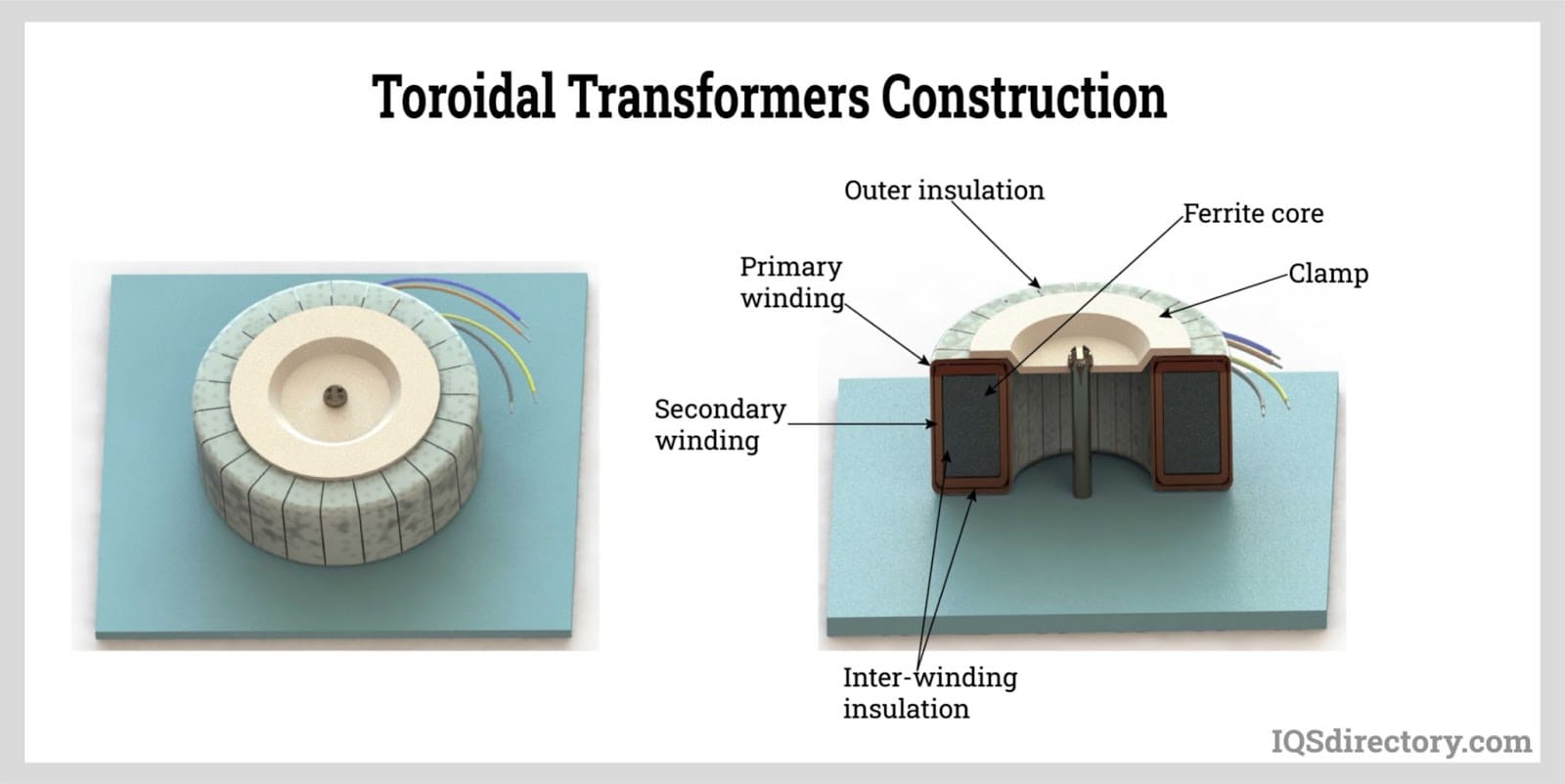

Bicron Electronics specializes in high efficiency toroidal transformers up to 10KVA with safety recognitions from UL, CSA, VDE, TUV and IEC as well as high frequency transformers up to 10MHz for isolation, gate drive, pulse and switch mode functions. Bicron is ISO 9001:2000 certified.

We design and manufacture Toroidal Transformers, Inductors and Current Transformers in Connecticut, USA and Asia. Certified to UL/CSA/IEC/EN. CE marking. Applications from lighting to medical devices. Customers served Worldwide. For High Frequency Magnetics, visit our affiliate www.Induktorusa.com

ISO 9001:2000 registered Sun Transformer creates custom transformers optimized for the needs of many industries. Large power, isolation & auto transformers, printed circuit mount power transformers, units for hostile conditions, units with ferrite or nickel cores for digital telecommunications use, etc.

More Zig Zag Transformer Manufacturers

What is a Zig Zag Transformer?

A zigzag transformer terminates the harmonics of the power system. It also safeguards the power system by lowering voltage stress during a fault event.

How a Zig Zag Transformer Functions

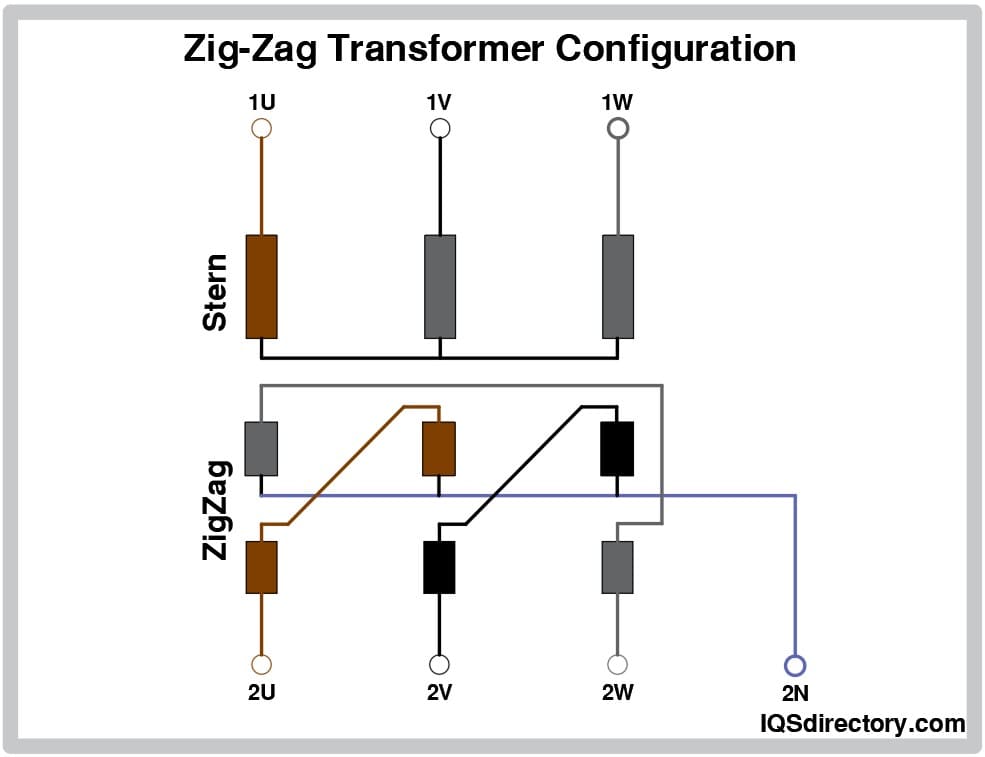

Although this sort of transformer connection isn't useful for converting electricity, it has a lot of advantages because it combines Star and Delta type winding connections. As illustrated in the diagram, the Zig Zag transformer has six coils, three outside coils, and three inside coils. ZIG winding refers to the outside coil windings, while ZAG winding refers to the interior coil windings.

The zig winding of one phase is connected in series with the zag winding of another phase, resulting in interconnected star winding in which two star winding coils are linked together. To cancel the mismatched voltages, two coil windings with the same number of turns are wound in opposite directions in each phase.

The connections of zig zag winding coils are shown below.

- The phase 'a' outer coil is coupled to the phase 'b' inner coil.

- The phase 'b' outer coil is coupled to the phase 'c' inner coil.

- The phase 'c' outer coil is coupled to the phase ‘a' inner coil.

The inner coil second terminals are joined together and connected to the neutral terminal to pass the zero sequence current components. A 30 phase shift occurs between the zag winding and the corresponding line to neutral voltage when distinct phase windings are connected. To achieve the same magnitude of voltages, the zigzag winding has 15.47% more turns than traditional transformers. As a result, the zig zag transformer is expensive, but it is required in certain applications.

Applications of Zig Zag Transformers

Zig Zag transformers have applications in:

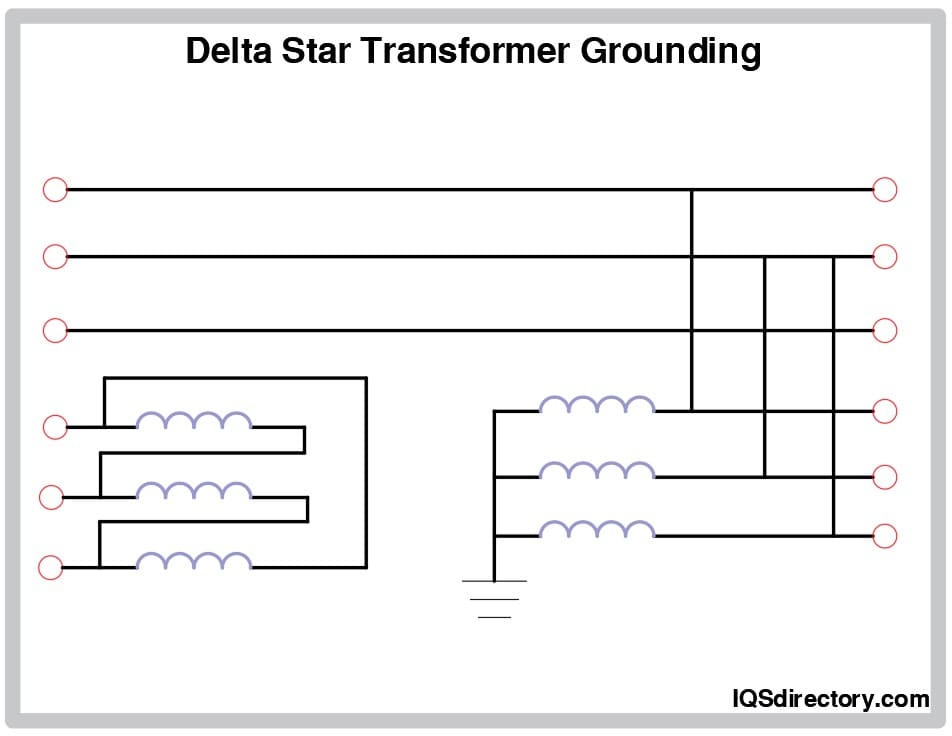

Grounding Transformer

It can be used as an earthing transformer in a delta connected (no neutral terminal) system or an ungrounded start connected (three terminal star) system where grounding is impossible. The earthing of the delta linked transformer is done with a zigzag transformer. There will be no path to zero sequence components in a delta linked transformer, and no safety can be provided for these components, increasing stress and heating in the windings.

During a line to ground failure, the zig zag transformer acts as a neutral, providing a channel to zero sequence components and allowing the protection to activate. In the absence of a grounded neutral, healthy voltages would increase line to line voltage, putting strain on the equipment's insulation. The Zig Zag transformer not only protects against symmetrical faults but also minimizes voltage stress.

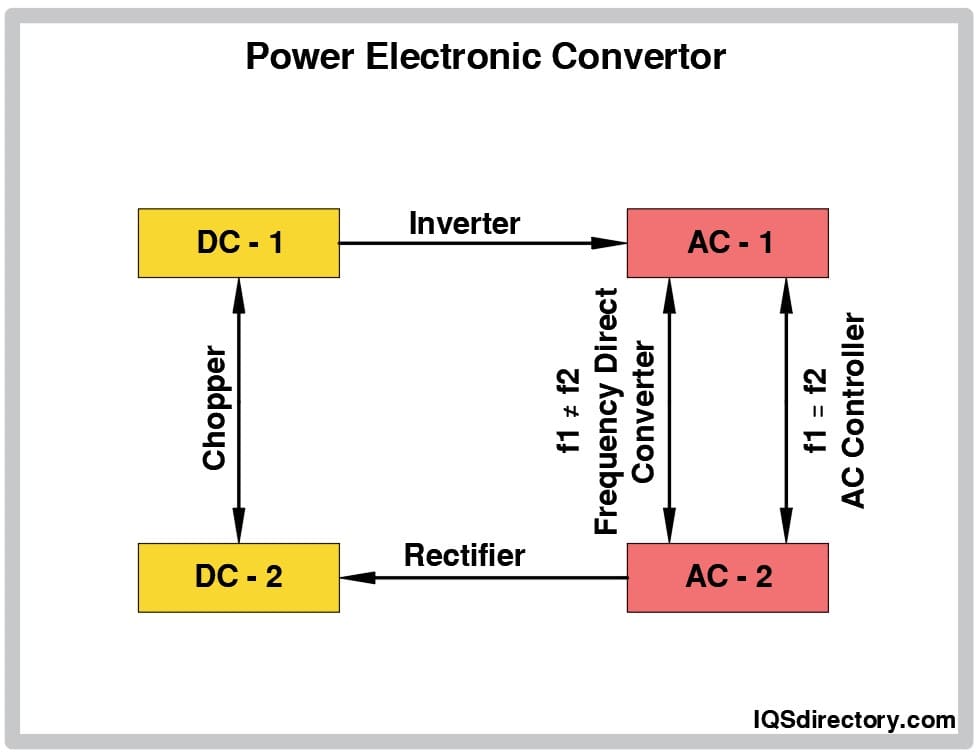

Power Electronic Converters

The zig zag transformer is used in power electronic converters to reduce the DC magnetizing component caused by incorrect firing angles. Due to the opposite direction of the DC magnetizing component of currents flowing in the windings on the same limb, inappropriate firing angles of power electronic components (SCR) may introduce DC magnetizing components. This is then negated in each limb of the zig zag transformer.

Earthing Reference or Earthing Transformer

Under fault conditions, the zig zag transformer provides a low impedance path to zero sequence components, making it ideal for an earthing transformer with an earthing reference. An appropriate resistor can be installed in the zig zag neutral terminal if the earthing current must be limited under fault conditions. Due to the opposing connection of winding coils, harmonic voltages in the system can be neutralized to some extent in zigzag windings.

Advantages of Zig Zag Transformers

- Compared to the Scott transformer, it is less expensive.

- It provides low impedance to zero sequence currents.

- It suppresses harmonic voltages.

- It ensures complete isolation between the ground and the component.

- It connects the delta connected transformer to the neutral and traps third harmonic current in the phase winding.

- Because there is no phase change between the main and secondary windings, delta – zig zag transformers are used similarly to star – star and delta – delta transformers.

- Zig zag transformers have a lower internal impedance than star connected transformers.

Choosing the Correct Zig Zag Transformer Company

To ensure the most beneficial outcome when purchasing zig zag transformers from a zig zag supplier, it is important to compare several suppliers using our directory of zig zag transformer suppliers. Each zig zag supplier has a business profile page illustrating their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or request a quote. Review each zig zag transformer company website using our patented website previewer for a better understanding of what each business specializes in. Then, use our simple RFQ form to contact multiple zig zag transformer companies with the same form.

Electric Coils

Electric Coils Electric Switches

Electric Switches Electric Transformers

Electric Transformers Electronic Connectors

Electronic Connectors Electronic Enclosures

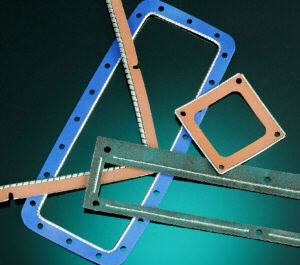

Electronic Enclosures EMI Shielding

EMI Shielding Membrane Switches

Membrane Switches Power Cords

Power Cords Static Eliminators

Static Eliminators Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services